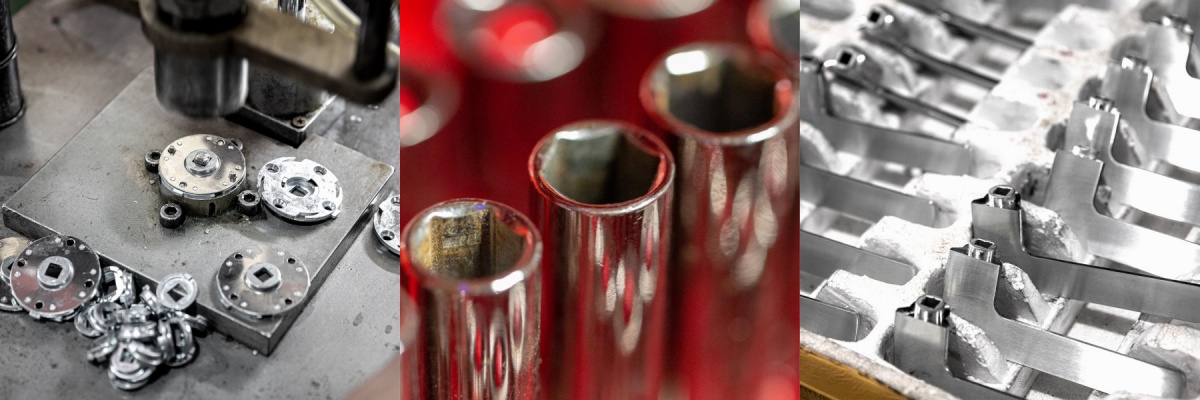

Tuag Casting

Cov txheej txheem tuag casting yog nias molten hlau rau hauv pwm nyob rau hauv kev kub siab los tsim ntau yam duab ntawm qhov rooj kho vajtse qhov chaw. Cov txheej txheem no yuav tsum tau ua kom tiav nyob rau hauv ib lub sij hawm luv luv los tiv thaiv cov hlau los ntawm txias thiab solidifying. Tom qab cov kua hlau yog txhaj rau hauv pwm, nws yuav tsum tau txias thiab solidified. Cov txheej txheem cua txias feem ntau ua tiav li ntawm ob peb vib nas this mus rau ob peb feeb, nyob ntawm qhov loj thiab cov duab ntawm ib feem. Tom qab txias, ib feem yuav raug tshem tawm ntawm pwm thiab ua tiav tom qab.

Tshuab dhos

Cov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob

CNC (Computer Numerical Control)

Cov txheej txheem CNC siv cov khoos phis tawj los tswj kev txav thiab ua haujlwm ntawm cov cuab yeej siv tshuab, thiab tuaj yeem ua tiav ntau yam kev txiav, milling, tig, drilling thiab lwm yam haujlwm ua haujlwm rau qhov rooj kho vajtse.

CNC tshuab cov cuab yeej tuaj yeem khiav tsis tu ncua yam tsis muaj kev cuam tshuam tib neeg, txhim kho kev tsim khoom zoo heev. Lub sijhawm ua haujlwm ntawm cov khoom nyuaj yog luv luv, thiab lub voj voog ntau lawm tau txo qis.

Los ntawm kev hloov cov kev pab cuam thiab cov cuab yeej, CNC tshuab cuab yeej tuaj yeem hloov kho sai sai rau cov kev xav tau ntawm cov khoom sib txawv. Qhov kev hloov pauv no ua rau cov txheej txheem CNC haum rau cov khoom me me, cov neeg siv khoom tsim qauv tsim.

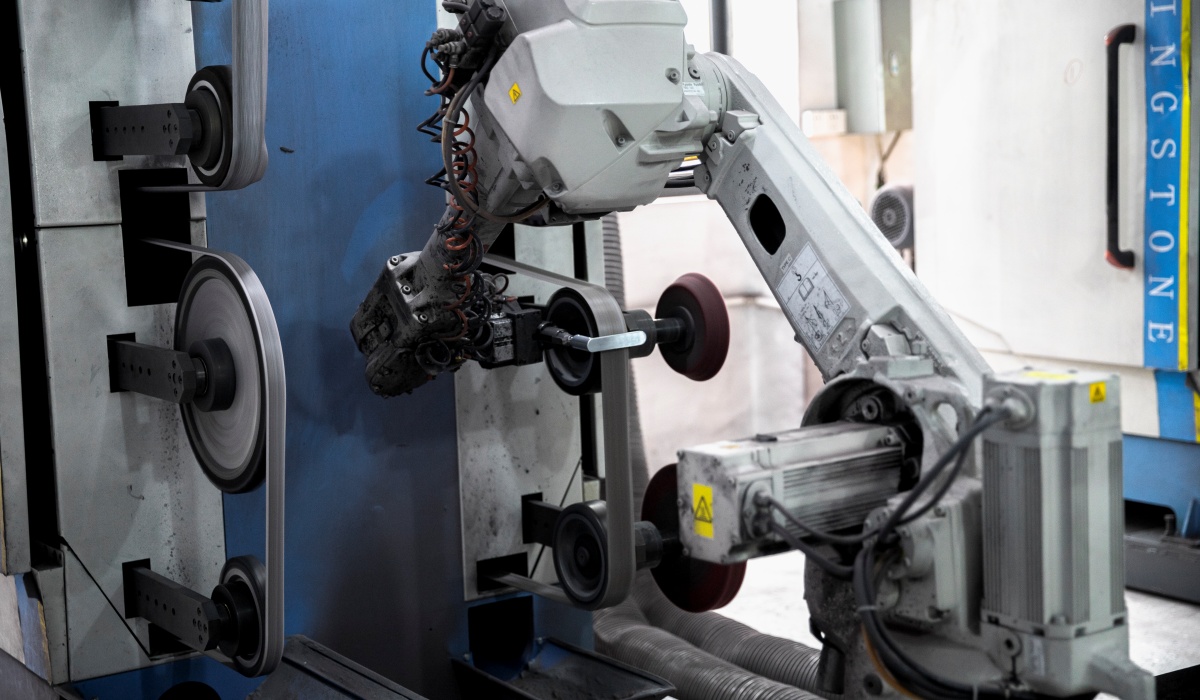

Polishing

Polishing yog ib qho tseem ceeb. Peb muaj peb tus kheej polishing cog nrog ib ncig ntawm 15 tus neeg ua haujlwm paub txog. Ua ntej ntawm tag nrho cov, peb siv ntxhib (loj abrasive grain) abrasive siv los txhuam cov "flashes" thiab "gate marks". Qhov thib ob, peb siv cov nplua (me me abrasive grain) abrasive siv los txhuam cov duab. Thaum kawg peb siv paj rwb log los polish qhov gloss nto. Nyob rau hauv txoj kev no, electroplating yuav tsis muaj cua npuas thiab nthwv dej.

Cov txheej txheem kho deg: electroplating / tshuaj tsuag xim / anodization

Tom qab cov impurities ntawm qhov chaw ntawm cov khoom kho vajtse raug kho, nws yog lub sij hawm los ntxiv xim. Cov txheej txheem no hu ua "electroplating" thiab cov khoom uas tau dhau los ua cov txheej txheem no hu ua electroplated qhov chaw.

Kev sib dhos

Kev sib xyaw ntawm tus kov thiab lub hauv paus: Muab qhov kov thiab lub hauv paus nrog screws lossis buckles, thiab xyuas kom meej tias kev sib txuas ntawm txhua qhov yog ruaj khov thiab tsis xoob.

Kev sim ua haujlwm: Tom qab sib dhos, ua qhov kev sim ua haujlwm ntawm lub qhov rooj kov kom ntseeg tau tias kev sib hloov, hloov thiab lwm yam kev ua haujlwm yog du thiab tsis muaj kev cuam tshuam.